클라우드 간 통신을 통한 시스템 통합

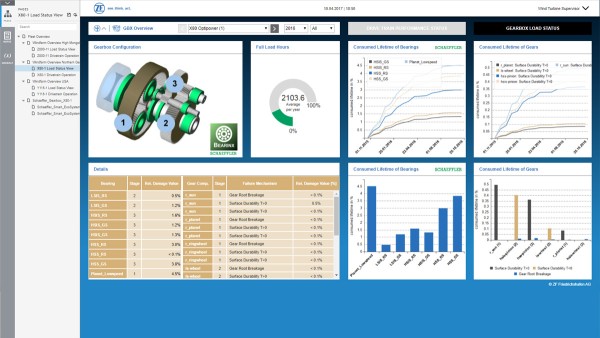

셰플러와 ZF Friedrichshafen AG의 제휴를 통해 풍력 부문을 위한 4.0 솔루션이 탄생했습니다. 두 파트너가 개발한 전문가 모델은 풍력 터빈의 운전 중에 발생하는 실제 부하를 기준으로 기어박스의 상태를 정밀하게 분석하고 예측합니다. 예를 들어 “LifetimeAnalyzer” 디지털 서비스는 공칭 잔여 유효수명을 계산할 수 있습니다.

ZF에서는 클라우드 간 통신을 이용하여 셰플러 엔지니어의 베어링 및 진동 해석 전문 지식을 자체의 디지털 모니터링 및 제어 시스템에 통합합니다. 셰플러 Smart EcoSystem은 고객과 파트너가 이러한 클라우드 간 솔루션을 사용하기 위한 필수 조건입니다. 이 디지털 에코시스템은 인터넷이나 VPN 연결을 통한 암호화된 통신과 표준화된 인터페이스를 사용하므로 개방형 아키텍처이고 최고 수준의 데이터 보안을 제공합니다.